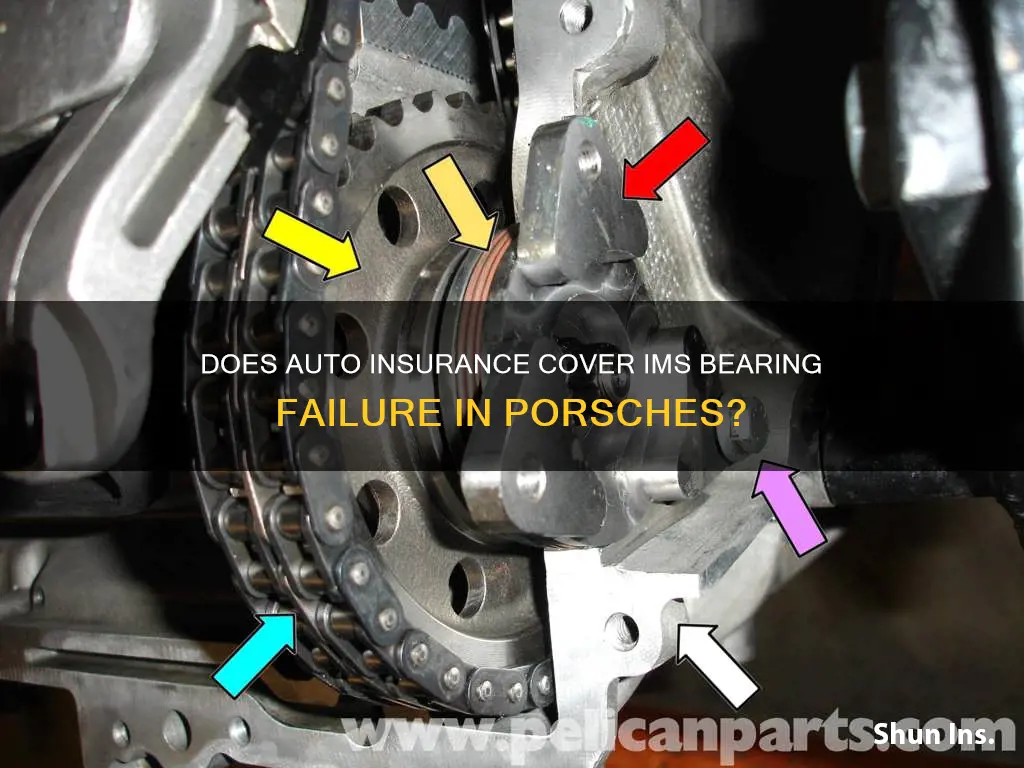

The Porsche IMS bearing is a small component that has caused big problems for Porsche owners. The bearing supports the intermediate shaft, which is used to drive the camshafts. The bearing was originally designed as a sealed, non-serviceable unit with lifetime lubrication. However, after years of use, oil and contaminants can seep past the bearing seal, wash out the original lubricant, and become trapped inside. This causes the bearing to wear out prematurely, leading to engine failure.

Porsche owners are advised to regularly inspect the IMS bearing and consider upgrading to a more reliable version to prevent costly repairs or even a complete engine replacement.

| Characteristics | Values |

|---|---|

| Does auto insurance cover IMS bearing Porsche? | No |

What You'll Learn

What is the Porsche IMS bearing?

The Porsche IMS bearing is a component of the intermediate shaft (IMS) in the engines of some Porsche models. The intermediate shaft is a geared shaft that runs through and extends out from the front and rear of the engine. Its function is to use the mechanical rotation of the engine's crankshaft to drive the camshafts on either side of the engine. The IMS bearing supports the intermediate shaft on the flywheel end of the motor.

The IMS bearing was introduced with the Boxster in 1997 and was also used in the Porsche 911 996 and 997, and the Cayman 987 models. The IMS bearing was designed to last the lifetime of the engine and did not have a specified service interval or replacement part number from Porsche.

The IMS bearing is a relatively small component, but its failure can lead to catastrophic engine damage and costly repairs. While there may not be obvious symptoms of a developing issue, signs of a failing IMS bearing may include metallic debris in the oil filter, an oil leak at the rear of the engine, or knocking and metallic sounds coming from the rear of the motor.

The failure of the IMS bearing is attributed to a combination of causes, including high load, insufficient lubrication, long drain intervals, high fuel and moisture content in the engine oil, and high oil temperatures. The exact failure rate is difficult to determine, but reliable sources have reported failure rates as high as 10% after an average of 90,000 miles.

To prevent IMS bearing failure, it is recommended to replace the bearing with an upgraded version, such as the IMS Retrofit kit or the IMS Solution, which is the only permanent fix. Regular oil changes, driving the car frequently, and avoiding higher gears to keep the revs above 2500-3000 rpm can also help extend the life of the IMS bearing.

LLC Auto Insurance: Owner Reimbursement?

You may want to see also

What is the function of the Porsche IMS bearing?

The Porsche IMS bearing is a component of the intermediate shaft (IMS), which is a geared shaft that runs through the engine and extends out of the front and rear. The function of the IMS bearing is to support the intermediate shaft and ensure that it can rotate smoothly. The intermediate shaft drives the camshafts indirectly off the crankshaft, and the IMS bearing is a key component in this process as it enables the rotation that drives the camshafts.

The use of an intermediate shaft has been a mainstay of the horizontally-opposed flat 6 engine utilised by Porsche. The inclusion of an intermediate shaft reduces the speed of the chains, which improves their performance and extends their lifespan. The intermediate shaft bearing, usually abbreviated as the IMS bearing, is typically a ball bearing that requires strong construction and sufficient lubrication to function effectively.

The IMS bearing was introduced to the Porsche around 1999 and has since been redesigned several times to improve its functionality and strength. Unfortunately, certain years of Porsche models are more prone to IMS bearing failures, with failure rates as high as eight percent under warranty. Outside of warranty, failure rates are believed to be even higher.

In summary, the Porsche IMS bearing plays a crucial role in supporting the intermediate shaft and enabling the rotation that drives the camshafts indirectly off the crankshaft. Its function is essential to the performance and longevity of the Porsche engine.

RV Gap Insurance: Necessary Protection?

You may want to see also

What are the common issues with the Porsche IMS bearing?

The IMS (Intermediate Shaft) bearing is a small but crucial component in the engine of Porsche Boxster and Porsche 911 996 models. The bearing supports the intermediate shaft on the flywheel end of the motor, allowing it to drive the camshafts on either side of the engine. While this basic design was used in Porsche engines for many years without issue, certain years of the Boxster and 911 models are more prone to IMS bearing failures. Specifically, the problem affects cars manufactured between 1997 and 2005, with failure rates as high as 8% or even 10% under warranty. Outside of the warranty period, failure rates are believed to be even higher.

The common issues with the IMS bearing in these Porsche models are primarily due to two factors: wear of the seal and design issues. The seal on the IMS bearing enables proper lubrication of the bearings. Over time, this seal can deteriorate, leading to inadequate lubrication and subsequent friction and grinding of the bearings. This can result in tiny metal shavings or fragments of black plastic ending up in the oil, which can be detected during oil changes.

Additionally, the IMS bearing in these models may be made of a material that is not sturdy enough to withstand the load exerted on it. The high temperatures in the engine as it runs further exacerbate the strain on the bearing, contributing to its premature failure.

It's important to note that Porsche introduced a stronger bearing in late 2005, reducing the likelihood of IMS bearing failure in subsequent models. However, for cars manufactured between 1997 and 2005, the potential for IMS bearing failure is a significant concern. The failure of this small component can lead to catastrophic engine damage and costly repairs, making it essential for Porsche owners to be vigilant about maintenance and proactive in addressing any signs of IMS bearing issues.

Insurance Primary: Yours or Theirs?

You may want to see also

What are the signs of a failing Porsche IMS bearing?

The IMS bearing in a Porsche is a small but crucial component in the engine. IMS bearing failure can lead to catastrophic engine failure and very expensive repair bills.

There are a few warning signs that your IMS bearing may be failing. Firstly, if you hear a loud rattling noise when you start the engine or accelerate, this could be a sign that your IMS bearing is close to failing. However, by the time you hear this noise, the damage is often already very costly. Therefore, it is important to regularly maintain your Porsche and look out for more subtle signs of IMS bearing failure.

One way to do this is to check for any metallic debris in the oil filter or used oil each time you change the oil and filter. If you find any metallic debris, it has most likely come from the balls within the bearing, indicating that the IMS bearing could be failing. Additionally, if you find fragments of black plastic, this may be from the IMS bearing seal. In both cases, you should take your car to a Porsche specialist for a full inspection and repair.

Another potential warning sign is an oil leak at the rear of the engine. However, most leaks in this area are from the RMS and do not always indicate a problem with the IMS bearing. Nevertheless, it is important to get any oil leaks checked by a Porsche specialist to determine the precise nature of the problem.

If you suspect that your IMS bearing may be failing, it is important to act quickly. Do not drive your car, as this could cause metal fragments from the bearing to damage key engine components, resulting in a much higher repair bill. Instead, have your car recovered to a Porsche specialist for an inspection and expert advice.

Direct Auto's Customer Service Number: Quick Access

You may want to see also

How to replace the Porsche IMS bearing?

How to Replace the Porsche IMS Bearing

Step 1: Purchase the Necessary Parts and Tools

Before you begin, you will need to purchase the necessary parts and tools for the job. You can purchase an IMS bearing upgrade kit from Pelican Parts or LN Engineering. You will also need the following tools:

- Removal, installation, and camshaft timing tools

- A bearing removal tool

- A bearing installation tool

- A 12mm socket

- A plastic hammer

- A small rubber hammer

- A pry bar

- A 24mm wrench

- A breaker bar

- A 13mm socket

- A screwdriver

- A torque wrench

- A diagnostic stethoscope

Step 2: Prepare the Vehicle

Jack up the car and remove the transmission, clutch, and flywheel. Drain the oil and remove and inspect the oil filter. Remove the camshaft end plugs from the engine.

Step 3: Remove the IMS Bearing Cover

Using a 10mm socket, remove the three bolts that hold the IMS bearing cover in place. Rotate the crankshaft until you see metal appear behind the through-holes. Insert set screws into the holes and tighten them down with a small tool or ratchet.

Step 4: Lock the Intermediate Shaft in Place

Mark the locations of the camshafts with marking paint or a scribe. Make sure the marks are clear and visible. Rotate the engine 360 degrees and double-check that the marks line up again perfectly.

Step 5: Remove the Tensioners

Loosen the two tensioners that pull on the flywheel-end sprockets of the intermediate shaft. Be sure to have an oil catch pan ready, as oil will spill out.

Step 6: Remove the Center Nut and Cover

Remove the center nut from the bearing. Tap the cover counterclockwise with two pry bars to get it off. If the center bolt drops into the recesses of the intermediate shaft, use a magnetic tool to pluck it out.

Step 7: Remove the Bearing

If you have a single-row bearing engine, remove the large circlip that holds the bearing in place. If you have a double-row bearing engine, the internal snap ring will snap out automatically when you pull the bearing. Use a bearing removal tool to thread the center bar onto the bearing stud and turn it until it reaches the base of the bearing. Slide the removal tool canister over the threaded rod and screw on the nut. Apply motor oil to the nut and the back surface of the tool to ease the removal process. Hold the threaded rod and turn the nut clockwise to remove the bearing.

Step 8: Clean the Intermediate Shaft

Get some paper towels and tape them to the end of a stick. Clean out the inside of the intermediate shaft. You can also attach a small rubber hose to the end of your shop vacuum and suck out any remaining debris.

Step 9: Install the New Bearing

If your bearing and center stud did not come pressed together, press the center stud into the bearing using a table vice. Place the bearing and tool assembly into the freezer overnight to shrink the bearing races and make installation easier. Place the bearing into the bore on the intermediate shaft and tap it into place with a plastic hammer.

Step 10: Install the Spacers and Spiroloc Clip

If you have a double-row bearing, install the outer spacer into the bore. Then, proceed to install the Spiroloc clip into the groove in the intermediate shaft.

Step 11: Install the IMS Bearing Cover

Place the smaller spacer on the backside cover. Tap the cover into place using a small rubber hammer. If you have a single-row bearing, install the big circlip and then the cover.

Step 12: Torque the Bolts and Nuts

Use new micro-encapsulated bolts to install the cover. Torque the bolts down to 8 ft-lbs (11 Nm). Place the O-ring on the center shaft and torque the 12-point nut to a maximum of 24 ft-lbs.

Step 13: Check the Camshaft Timing

With the new bearing installed, you are almost done. However, it's important to check your camshaft timing before reinstalling the transmission and starting the engine. Use the factory PST-2 tool or the Durametric tool to compare the deviations in the timing between the two camshafts. If the timing is off, you will need to retime the cams.

Bundling Auto and Motorcycle Insurance: Worth It?

You may want to see also

Frequently asked questions

The Porsche IMS bearing is a small component that can cause big problems. It supports the intermediate shaft, which is crucial for operating the camshafts.

The Porsche IMS bearing stabilises the intermediate shaft.

If the Porsche IMS bearing fails, the timing chains on the engine may disengage, and the engine will quickly self-destruct.

When you first start your car, you may hear a loud rattling noise that goes away after about 10 seconds. When you accelerate, you may also hear this noise too.